Customer Care:- 08045816650

Product Range

We are engaged in manufacturing, supplying and exporting of

various products which are made from high quality raw materials and

components. Highly durable and operationally superior, these are widely

used in Power Plants, Sugar Plants, Cement Plant, D.G Sets etc. Our

range of products is as follows:

Bellows Assembly

1) Axial Bellows

2) Rectangular Bellows

Expansion Bellows

1) Double Bellows

2) Hinged Bellows

3) Universal Bellows

4) Gimbal Bellows

Pressure Bellows

1) In-Line Pressure Balanced Bellows

2) Pressure Balanced Bellows

Quality Compliance

Shah Expansion Joints (Bellows) Manufacturersis a quality driven

company as it follows a Quality Management System in all aspects of

business. All written work instructions are followedat initial stages of

the production. The quality checking of products, like axial bellows,

hinged bellows,pressure balanced bellows, in line pressure balanced

bellows,double bellows, universal bellows, expansion bellows, expansion

joint bellows, etc., continues with inspection, process controls and a

last review of compliance to the requirements dictated by clients. Every

person in the company is a part of the Quality Assurance Team, that

adds quality to the products at each and every stage of the production

process.

Our personnel abide by following process to maintain high level of quality standards:

1) All drawings are carefully inspected before release

2) Qualified engineers and draftsmen make use of high-tech equipment and international codes of practice

3) Raw materials are sourced and checked to rigid specifications

Expansion Bellows /Hoses are manufactured in our manufacturing

unit with delivery schedules as the client requests, and the said

products are manufactured by trained employees making use of advanced

machinery and under strict quality assurance controls.

We value our long-standing business relationships with out

clients and therefore adhere to honesty, integrity and efficiency at all

levels. We are committed to continuously improve all our systems and

never compromise on the quality.

Quality Assurance

Our quality centric approach is our top priority. This commitment

initiates at the enquiry stage. The industrial bellows are designed by

our designers making use of the software developed by our engineers.

They analyze effects on pipe from restraint loading and develop the most

affordable and carefully tested designs in the industry. The provided

industrial bellows are supported by innovation, engineering expertise

and expert service to make sure that clients are completely satisfied.

Infrastructure & Facilities

Our technological excellence is exhibited in out infrastructure.

Our high technological foundation makes Shah Expansion Joints (Bellows)

Manufacturers superior. Our experience and expertise enable us to

continually adopt the latest in product development and manufacturing

technology. There are different departments, shops and facilities in our

factory, which are tool and machine shop, design, machining, molding,

CAD/CAM and inspection. The CAD/CAM facility is incorporated in the

design unit, which assist in coming forth with innovative and efficient

product designs. The products designed in this unit are pressure

balanced bellows, universal bellows, axial bellows, in line pressure

balanced bellows, double bellows, hinged bellows, etc. There are many

machines employed in the tool room, such as:

- Furnaces

- CNC turning centers

- Cutting machines

- Milling machine

- Lathes

- Surface grinders

- Molding machines

- Chemical De-scaling System

The horizon of the company is extended by the combination of technology, competent team and their vision to lead.

Research and Development

In our business strategies, R&D activities are critical in

the development of business. Therefore, we work towards the development

of new products using technologies that have maximum growth potential

and predict industrial requirements in near future. Our research team

works with clients to provide them quality and innovative bellows. They

also find ways to improve the production process to promote better

utilization of resources. Our research specialists carry out the process

capacity analysis so that production process can be made more

efficient. The feasibility and efficiency of the new development in line

with the products and services are tested and then recommended to the

production or design department.

Wide Distribution Network

The determination and efforts have led to the development of a

well-organized business network that has its presence in many foreign

lands. Because of this network, we are today able to time and

efficiently distribute the products in Indian as well as foreign

markets, such as Greece, Germany and Singapore.

Research & Development Facilities

Testing Facilities : Our professionals are continually coming up

with new methods of designing and developing bellows technology. They

can perform all types of non-destructive testing, for instance:

- Radiography

- Mass Spectrometer

- Ultrasound

- Magnetic Particle

- Hydrostatic and Liquid Penetrant Inspection

As per the clients request, we can also perform cycle testing,

pneumatic testing, spring rate testing, impact testing,helium leak

detection and positive material identification (PMI). The design,

quality control and manufacturing process are in line with the codes and

standards, such as EJMA, ASME Section VIII and IX, ANSI B31.1, B31.3

About Installation of Bellows

It is a fact that bellow is not a hardware component that can

take up weights and misalignments due to improperly designed piping

system. The bellows must be install following an instruction that is

according to the recommendations of EJMA.

Metal Bellows Expansion Joints can absorb a particular amount of

movement as these can flex their thin-gauge convolutions. Therefore,

proper and careful installation is the key, as the incorrect

installation can cause reduced cycle life and the pressure capacity of

the expansion joints. It will further cause early failure of the bellows

element or can damage the piping system.

The most common installation errors can be avoided by following

these recommendations. If the client is uncertain about the installation

process, he must contact the manufacturer/piping design engineer for

clarification before continuing the Expansion Joint installation

process. Besides following the instructions of a pipe design engineers,

the piping system must haveproper supports hangers, etc.

Our Diligent Personnel

A highly talented team is created, the members of which work on

the commitment to design and develop qualitative and innovative bellows,

like axial bellows, hinged bellows,expansion bellows, expansion joint

bellows, double bellows, universal bellows, pressure balanced bellows,

in line pressure balanced bellows,etc., and other expansion joints. The

highly experienced and trained professionals carry out tasks in

conformation with the industry standards and specifications provided by

the customers. Our team includes following members:

- Designers

- Engineers

- Production engineers

- Instrumentation control engineers

- Technocrats

- Quality controllers

- Research and development experts

All team members know how important is every stage of order

processing, from designing, engineering, quality control and packaging,

they make best use of resources to develop flexible hoses, bellows and

bellow seals.

Designing and Engineering

The GMP standards are followed to comprehend the requirement to

international standardized designing and manufacturing techniques to

offer world-class bellows, like in line pressure balanced bellows,

expansion bellows, expansion joint bellows, etc., that stand apart from

others. As GMP practices have in-built Q-C methods, our team follows the

following methodologies while manufacturing the bellows to filter them

as per design and quality:

1) Identification of raw material by mechanical /chemical analysis by approved lab.

2) Radiography examination for welded parts if needed.

3) Pressure testing for testing leakages of parts and assembly.

4) Surface defects and weld integrity checks by liquid penetrant examination prior and post cold work.

5) Magnetic practice and ultrasonic test by third party agency.

6) Dimensional verification of parts and assembly.

7) Helium leak test by agency for bellows to cryogenic applications.

Clientele

Seamless and hassle-free processes are followed to achieve

customer satisfaction. Client-centric policies are adhered as we give

significance to our customers and their requirements. We welcome their

feedback and suggestions, and incorporate them. We have become a

preferred choice of clients because of our commitment towards quality

and our principled way of working. Their level of confidence in our

company is further enhanced by providing customization facilities and

strictly adhering to delivery deadlines.

We have had the privilege to work with following entities, which include:

- All government sectors

- Fertilizer plants

- Steel plants

- Private sectors

- Cement plants

- Engineer & consultants

- CQAE DGQA, BARC

Industrial Applications

In order to protect critical components, bellows are required.

The company started years ago manufacturing bellows and expanded he

product line over the years. Different types of bellows are offered by

us, which are needed in so many applications. The major demand arises

from the following areas:

- Sugar Plant

- Heavy Industrial

- Petrochemical

- Power Generation

Quality Assurance

Offering excellent quality of products is our business mantra. We constantly endeavor to uphold our quality parameters and for the purpose have adopted a stringent quality policy. We lay strong emphasis on the quality of raw material and components, as it ultimately affects the quality of our final products. All our product like Hinged Bellows, Metal Bellows, Mechanical Seals etc goes through extensive quality check at every stage of production. Some of the tests we conduct to evaluate the quality of our products are as follows:

- Ultrasound

- Mass Spectrometer

- Magnetic Particle

- Hydrostatic and liquid penetrant inspection.

We can also perform other tests such as cycle testing, spring rate testing, impact testing, pneumatic testing, helium leak detection and positive material identification (PMI) as per requests of clients. All our products are designed as per latest standards of EJMA/ASME.

Infrastructural Facilities

To provide our customers with best quality of Universal Bellows with Pipe / Flanges, Metal Bellows, Hinged Bellows, Mechanical Seals, Gimbal Bellows etc., we have developed a large infrastructure base in Ahmedabad. Furthermore, to carry out uninterrupted production, we have segregated our infrastructure into various units such as manufacturing unit, quality control unit, packaging unit, etc. The right combination of experienced manpower, modern processing facility and new technology assists us in manufacturing bellows, expansion joints and piping assemblies from 40NB nominal diameter to 2000 NB, and thus meet the ever increasing demands of various markets. In addition, we also recruit a team of researchers, designers and engineers who work hard to maintain the quality and other features of our products. Utilizing their expertise, they conduct exhaustive market, product and consumer surveys to ensure that offered products are in sync with the growing technology.

Our Strength

With our world class product portfolio, we have emerged as front runners in our domain. A few reasons behind our booming success are underlined below:

- Advanced manufacturing unit

- Stringent quality check

- Efficient professionals

- Transparent dealings

- Timely delivery of consignments.

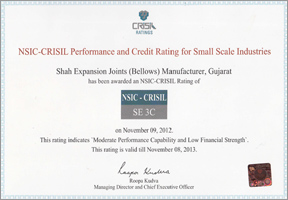

CRISIL UKAS and ISO 9001:2008 certification |